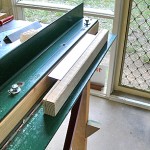

The hat stiffeners for the spar webs proved to be quite a task for such a small item. The difficulty was getting the multiple bends done. It involved a number of processes including making various jigs and spacers, then a fair bit of finishing to get the angles right.

See photos.

5.5 Hours.