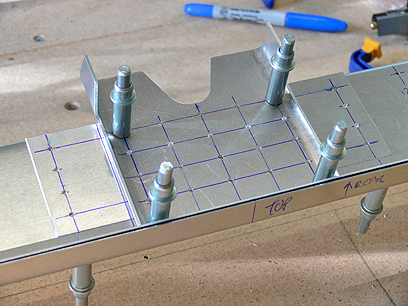

Having cut the stabiliser spar blanks from sheet, I attempted folding them on the home made brake. I spent a few hours trying to rectify curving of the part along its length. I cleaned faces of bending plates, then worked out that the curving is caused by slipping in the centre of the material when in the brake – I found this could be remedied to a degree by not tightening near the end, but only the centre bolts and no bolts beyond the material.

This worked to a degree but I also found that the brake top plate was moving slightly during bending. I drilled new holes and got bolts that ran right through the bench to replace the coach screws.

I began looking at alternative methods. I made a long straight form block from KD Hardwood in an effort to bend the flanges by hand, but upon removing from the form block I had a curving piece.

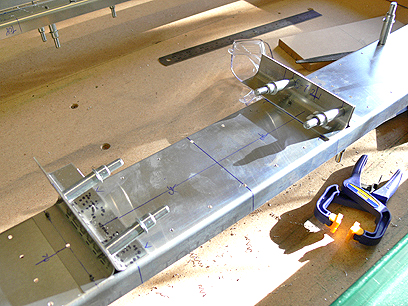

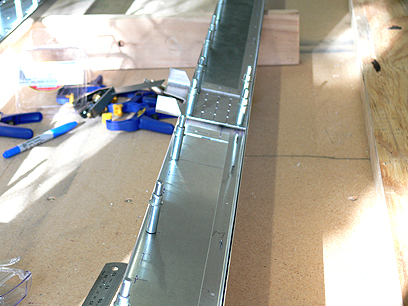

I eventually hit upon a method where if I left some extra metal on the blank so it went past the brake bolt holes, I could drill through those holes with the sheet in-situ and bolt the brake flanges in place, then bend. This was a breakthrough, the parts came out perfectly. I Succeeded in making stabiliser rear spar of good standard.

I later found however, that when making the doublers, after trimming them down to the required 19mm wide flanges, they still showed a slight curve. However, this was small enough so as not to prove a problem, given they would straighten out easily when clecoed in place.

This only proved to be a problem with heavier gauge 6061. Anything 25 thou or less didn’t suffer from this.

It took several sessions, including re-making 6-T-2 2 after discovering radius should be 1/4?, not 1/8? as per the Zenith Construction Standards for anything over 0.040”.

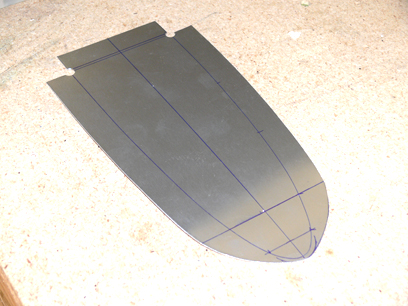

There’s a bit of fiddling around fitting the rear spar attachment, and first you need to make the cutouts as per the plans. You should get an idea from the photos. And the shims need to go in while you’re at it.